Is lithium battery safe?

The differences between traditional blended batteries and super blended batteries

The fundamental difference between traditional blended batteries and super blended batteries lies in the technological leap of a new generation. It is akin to the transition from feature phones to smart phones, not only involving parameter improvements but also a comprehensive revolution in the driving experience. The super blended battery, through material innovation and system reconfiguration, has completely redefined the value positioning of blended vehicles.

Core positioning differences: From "transition solution" to "main choice"

Traditional blended battery: As a transitional product for fuel vehicles to electric vehicles, the design concept is "sufficient is enough", with a capacity of 10-20 kWh, and pure electric range of 100-200 km. Essentially, it is "auxiliary power supply", mainly addressing short-distance commuting and fuel consumption anxiety.

Super blended battery (taking Xiaoyao as an example): Positioned as a "full-domain energy solution", the capacity is increased to 30-50 kWh, and the pure electric range exceeds 400 km. The goal is "pure electric as the main source, hybrid as the auxiliary", meeting 90% of daily commuting pure electric needs, and eliminating range anxiety in long-distance scenarios.

Technical Architecture: From "Single Chemical System" to "Synergistic Integration"

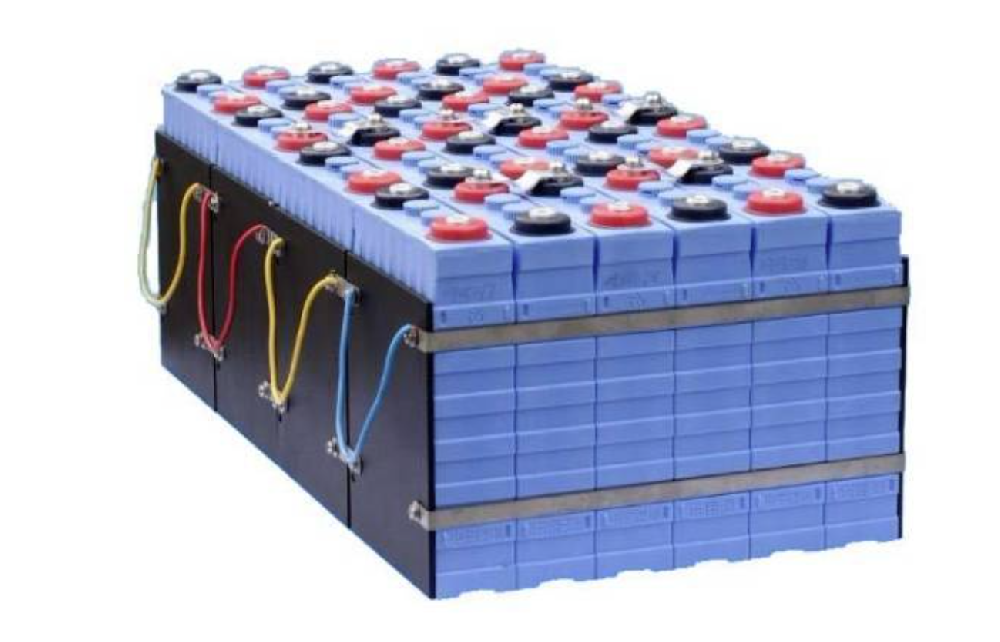

Traditional Hybrid Battery: Single Lithium Battery + Infrastructure

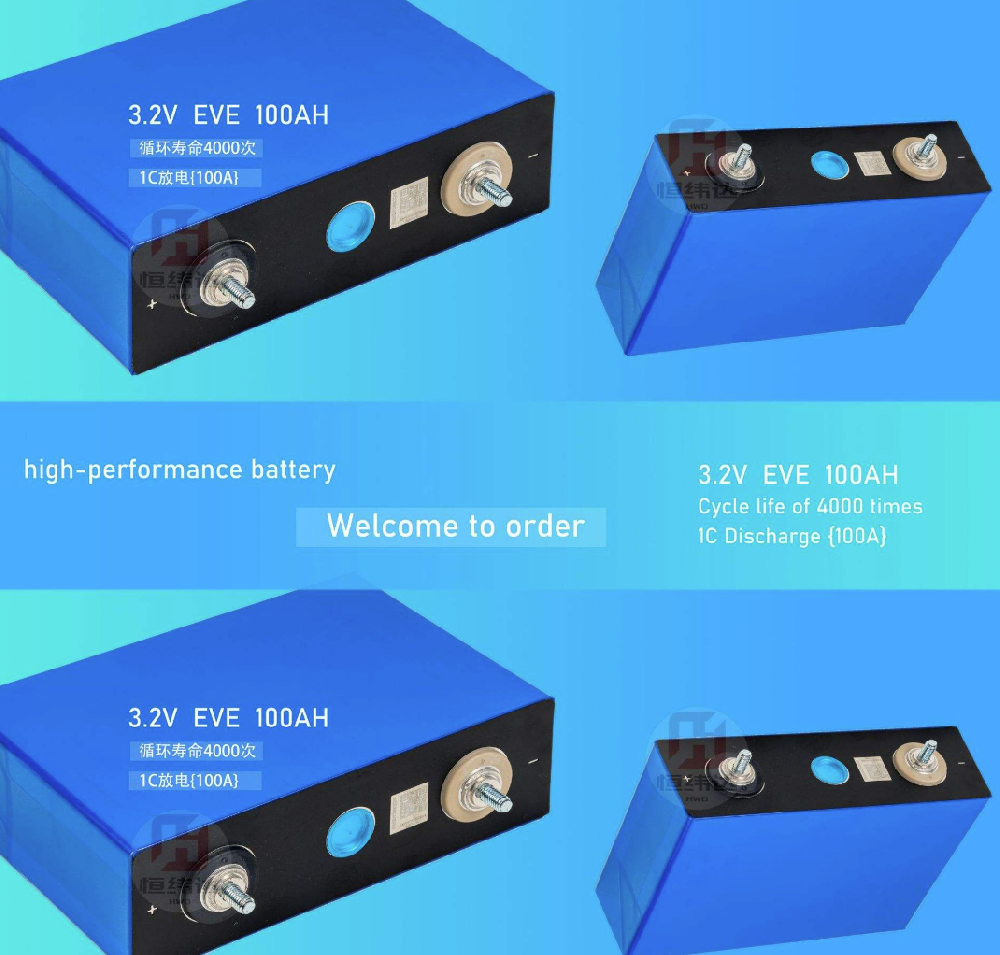

Material Limitations: Commonly use lithium iron phosphate or low-nickel ternary lithium, with an energy density of 150-200 Wh/kg, and a charging rate of ≤ 1C (fast charging requires more than 1 hour).

System Simple: The battery pack only performs basic integration, without intelligent thermal management, with a -20°C low-temperature range of battery endurance degradation exceeding 30%, and a high-temperature cycle life of less than 2000 times.

Super Hybrid Battery: Sodium-Lithium Synergy + Intelligent System

Material Revolution:

Sodium-Lithium AB Battery (such as Xiaoyao): Lithium battery ensures energy density (silicon-based negative electrode + high-voltage positive electrode, 253 Wh/kg), sodium battery improves low-temperature performance (-40°C dischargeable) and fast charging speed (4C ultra-fast charging, 10-minute replenishment of 280 km).

Structural Innovation: Multi-gradient electrode sheets, ceramic separators, nano protective coatings, reducing the probability of thermal runaway by 90%.

Intelligent Synergy:

BMS algorithm dynamically allocates sodium-lithium output, sodium battery dominates discharge in low-temperature scenarios, and lithium battery precisely controls temperature in high-temperature scenarios.

Support V2G vehicle-grid interaction, extending battery lifespan from 10 years to 15 years (4000 cycles).